Standard extruded heatsinks

Showing 1–24 of 382 results

-

Standard extruded heatsinks

10 AS 100

If you are interested in this product, please write us at contact@heatsink.eu and request for quotation for custom size products.

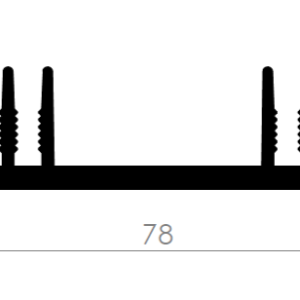

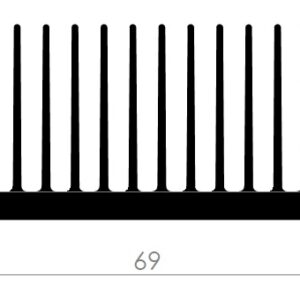

Type: Heatsink Extrusion Material: Aluminum 6063-T5 Surface Black or Natural Anodized Height: 20mm Width: 78mm Length: 100mm SKU: n/a -

Standard extruded heatsinks

10 AS 100

If you are interested in this product, please write us at contact@heatsink.eu and request for quotation for custom size products.

Type: Heatsink Extrusion Material: Aluminium 6063-T5 Surface Black or Natural Anodized Height: 20mm Width: 78mm Length: 100mm SKU: n/a -

Standard extruded heatsinks

10 AS 120

If you are interested in this product, please write us at contact@heatsink.eu and request for quotation for custom size products.

Type: Heatsink Extrusion Material: Aluminium 6063-T5 Surface Black or Natural Anodized Height: 20mm Width: 78mm Length: 120mm SKU: n/a -

Standard extruded heatsinks

10 AS 150

If you are interested in this product, please write us at contact@heatsink.eu and request for quotation for custom size products.

Type: Heatsink Extrusion Material: Aluminium 6063-T5 Surface Black or Natural Anodized Height: 20mm Width: 78mm Length: 150mm SKU: n/a -

Standard extruded heatsinks

10 AS 200

If you are interested in this product, please write us at contact@heatsink.eu and request for quotation for custom size products.

Type: Heatsink Extrusion Material: Aluminium 6063-T5 Surface Black or Natural Anodized Height: 20mm Width: 78mm Length: 200mm SKU: n/a -

Standard extruded heatsinks

10 AS 250

If you are interested in this product, please write us at contact@heatsink.eu and request for quotation for custom size products.

Type: Heatsink Extrusion Material: Aluminium 6063-T5 Surface Black or Natural Anodized Height: 20mm Width: 78mm Length: 250mm SKU: n/a -

Standard extruded heatsinks

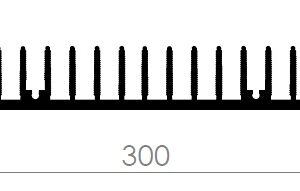

10 AS 300

If you are interested in this product, please write us at contact@heatsink.eu and request for quotation for custom size products.

Type: Heatsink Extrusion Material: Aluminium 6063-T5 Surface Black or Natural Anodized Height: 20mm Width: 78mm Length: 300mm SKU: n/a -

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-